Features

Main Steel Frame

After the welding of the frame is completed, it is placed for one month, and then heat treated;

Eliminate the residual stress generated during the machining process;

Change the crystal structure inside the material;

Enhance the stability of the subject;

Afterwards, it will be treated for 6 months;

Then send to the machining center for precision machining.

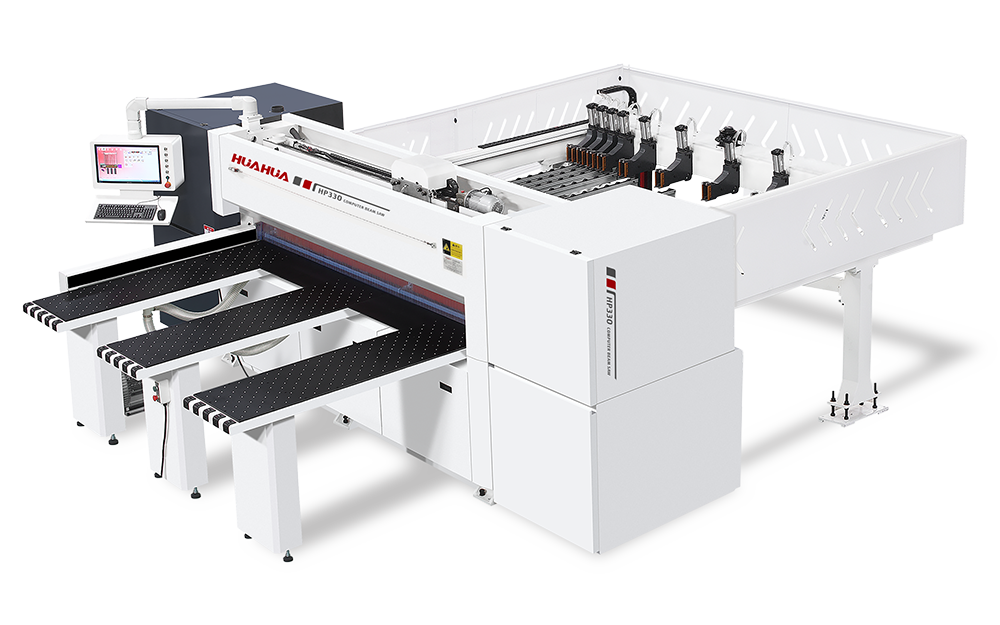

Industrial PC Control System

1) Easy to operation, safety & reliable;

2) Which has complete operating hints and troubleshooting guide functions;

3) It’s cutting plan can edit manually; can simulate or execute cutting plans;

4) Can compatible with bar code manage software or factory automation software.

Pneumatic Clamping

The industry-leading two-finger clamping structure is adopted, panel is clamped by air cylinder, before feeding, passing the roller conveyor to ensure the cutting accuracy without damaging panel surface.

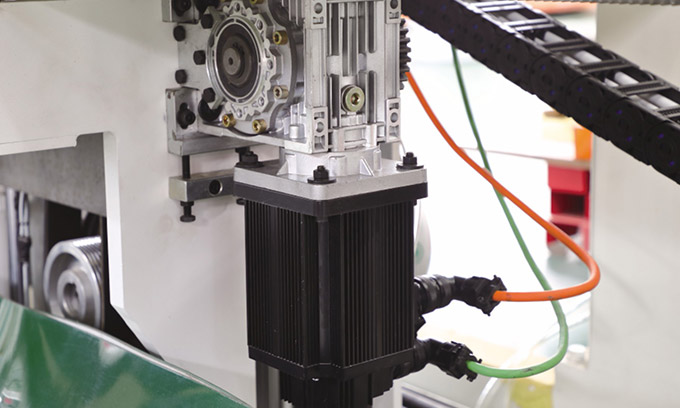

Saw Carriage Drive Servo Motor

Equipped with 2kw servo motor, saw carrigae power reducer, gear reducer three-phase asynchronous motor, make sure high efficiency and stable cutting.

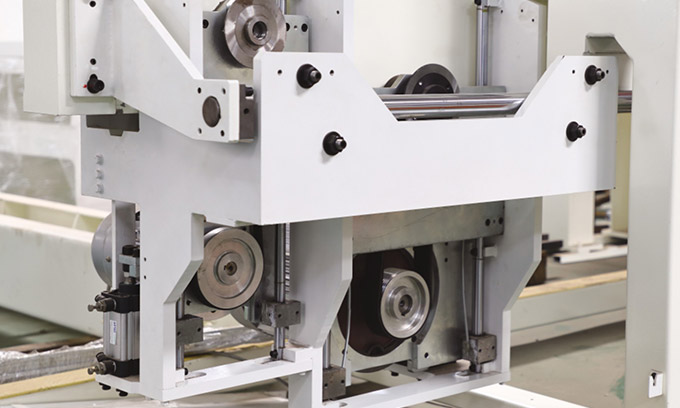

Saw Carrige

Main saw and scoring saw are lifted and lowered independently, sawing stroke can be automatically positioned according to different cutting thickness and width. standard 18.5kw main saw motor is equipped, saw blades fastly replace, which effectively reduces the burden on workers.

Roller Conveyor

Rollers assist the panel moving, protect surface of the panel and prevent scratching, heavy panel is easy to move too.

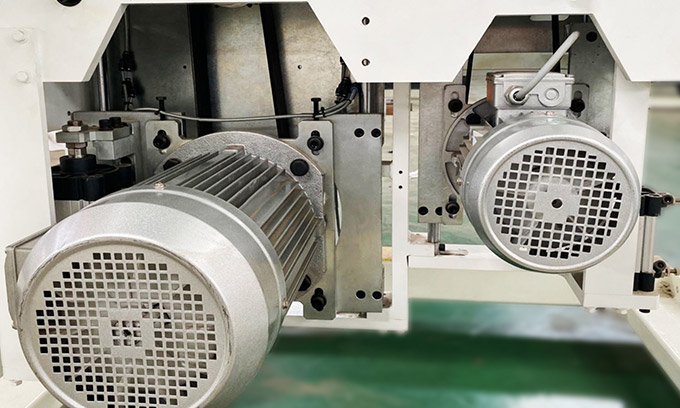

Saw Carriage Lifting Mechanism

18.5kw motor, main saw shaft rotation speed is 4000rpm, precision reducer can automatically adjust the cutting height according to the panel thickness, high speed, stable, and flexible.

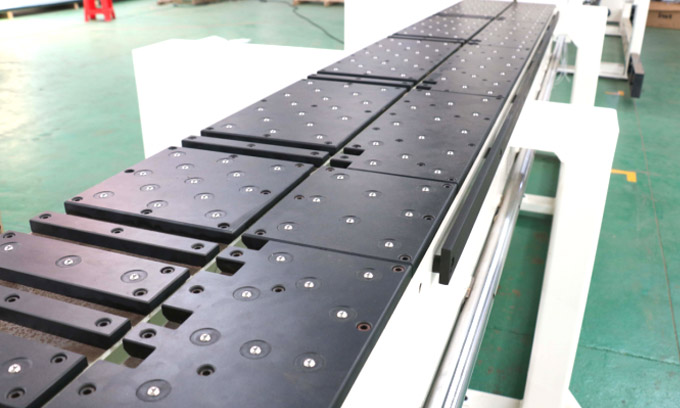

Cutting Bench

1.with air Floating bead, easy to move the board and Avoid scratching on board;

2.The design of the sawing table is upgraded, which is narrower than the traditional bench;

The advantage is that it is not easy to sink or deform.

And cutting panel edge is not easy to burst.

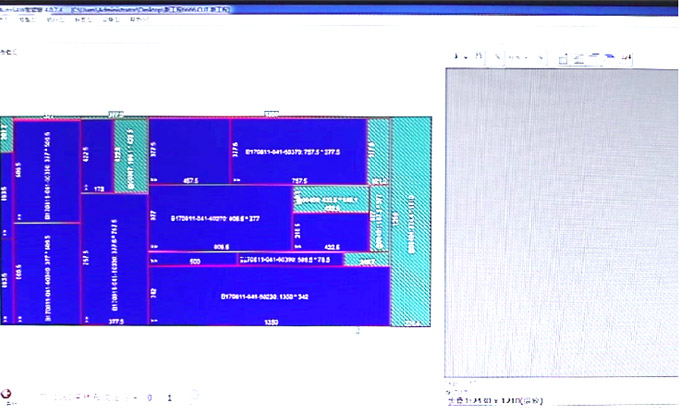

Optional Cutting optimization software

Automatic calculate system,

Cutting plan layout system,

Remains management system;

Greatly enhance user productivity, reduce production costs, increase revenue, and improve the panels utilization rate.

Optional Side aligner device

Fix cutting panel width side, control panels not move or shake when sawing, ensure width sawing precision.

Pressure can be adjusted according to difference thickness, weight and material, ensure the precision of sawing dimension.