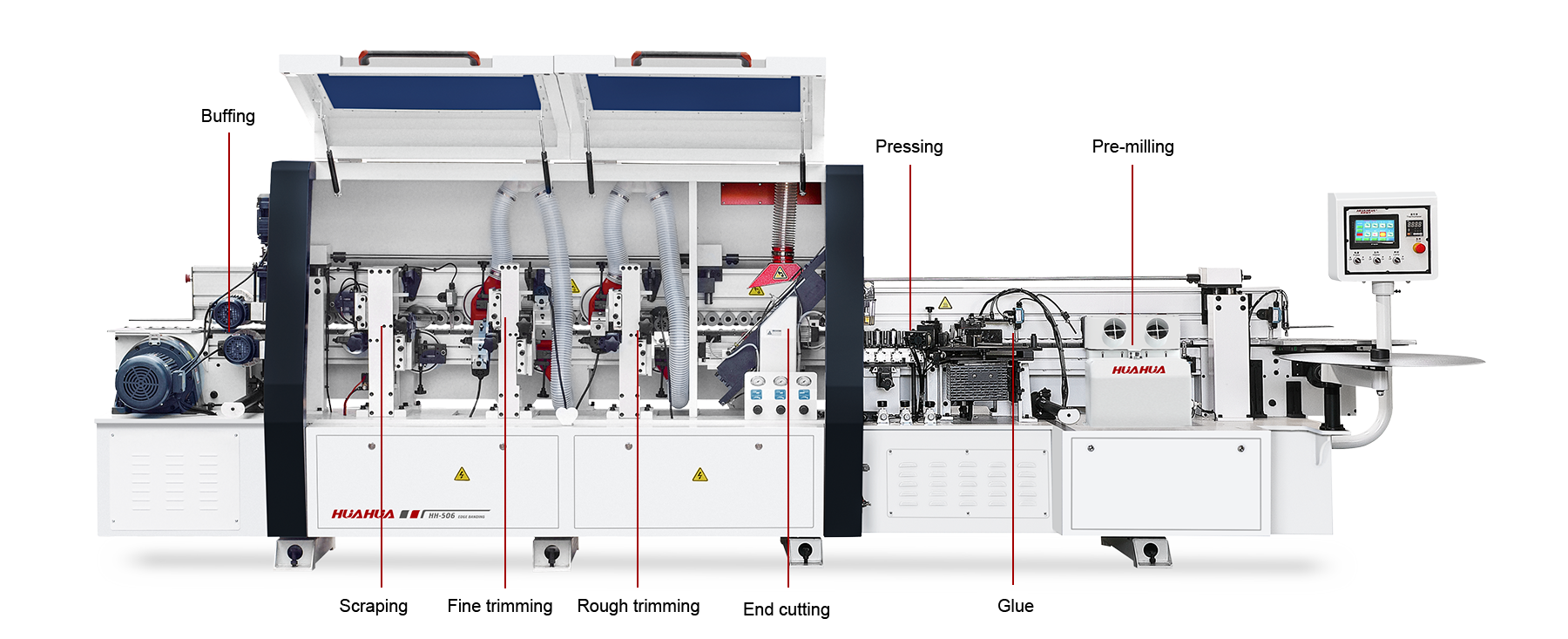

Features

7 Inch Color Control Screen

It adopts touch color screen display, which is easy to operate, saves space, safe and reliable in operation, simple and friendly interface, with complete operation prompts, concise and clear.

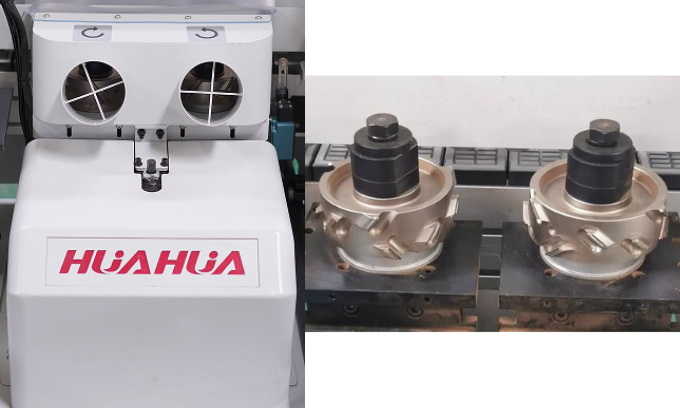

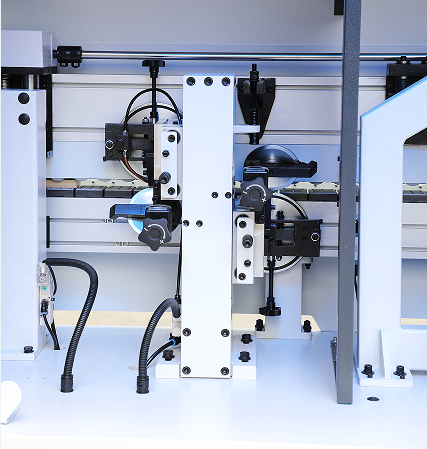

Pre-Milling

Trimming the edge of the panel after cutting

Equipped with a 2.2KW high-power motor, it is composed of two milling tools at the front and rear. The maximum pre-milling height is 40mm (65mm is optional).

Milling the corrugated of the surface of the board makes the edge banding and the board more tightly bonded, and the integrity and aesthetics are better.

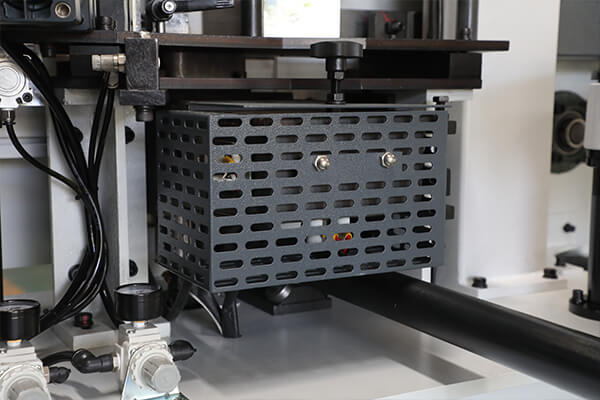

Glue Pot

Short time to Reach Operating Temperature. the Tool Free Quick Change System Guarantees Quick Cleaning and Change over Times when Changing the Glue or Colour. the Synchronised, Fine Adjustable Glue Roller Ensures the Right Application Amount Of Glue.

End Cutting Unit

Through the precise linear guide rail movement, the automatic tracking of the profile and the fast cutting structure of the high-frequency high-speed motor are used to trim the protruding edge banding strips at the front end of the plate and the protruding edge banding strips at the rear end of the plate.

Make it flush with the front and back ends of the sheet to ensure that the cut surface is flat and smooth.

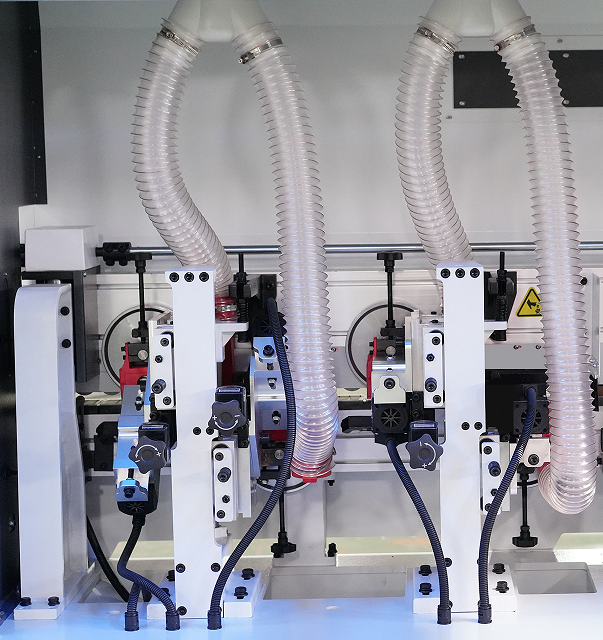

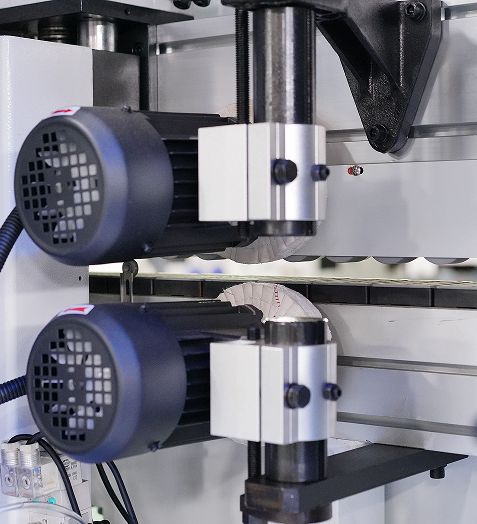

Rough & Fine Trimming System

Use The large and small discs to automatically track the high-frequency and high-speed motor structure, trim the edge banding strips bonded on the upper and lower sides of the plate, and remove the excess edge banding material on the upper and lower sides of the processed plate edge banding strips, so that it can be milled into an R-shaped edge.

Scraping Unit

The edge trimming knives on both sides of the board scrape off the wavy knife marks caused by the rotation on the edge banding, and the modified R angle is the same as the R angle after finishing, making the upper and lower parts of the board more smooth and tidy.

Buffing Unit

Through the two rotating cloth wheels, the processed panel is cleaned to make the end face of the edge banding more smooth and beautiful, and to keep the polishing wheel worn evenly.