Features

Automatic positioning of pressure beam

Automatically adjust the lifting height of the saw blade and pressure beam according to the thickness of the plate, eliminating the need for manual adjustment, ensuring the stability of the pressure beam and greatly improving equipment safety.

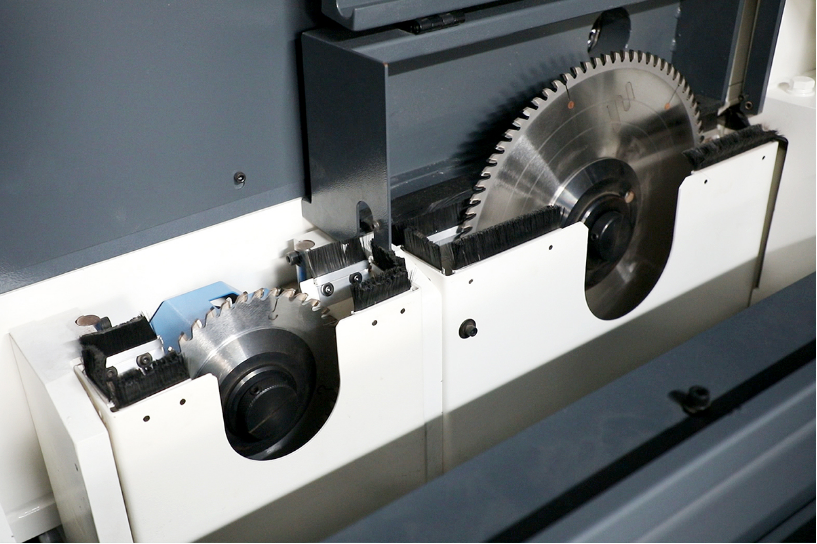

Large and small saws can be lifted independently

According to the thickness of the board, the sawing stroke is automatically positioned to reduce idle time, and the saw base speed reaches 120m/min.

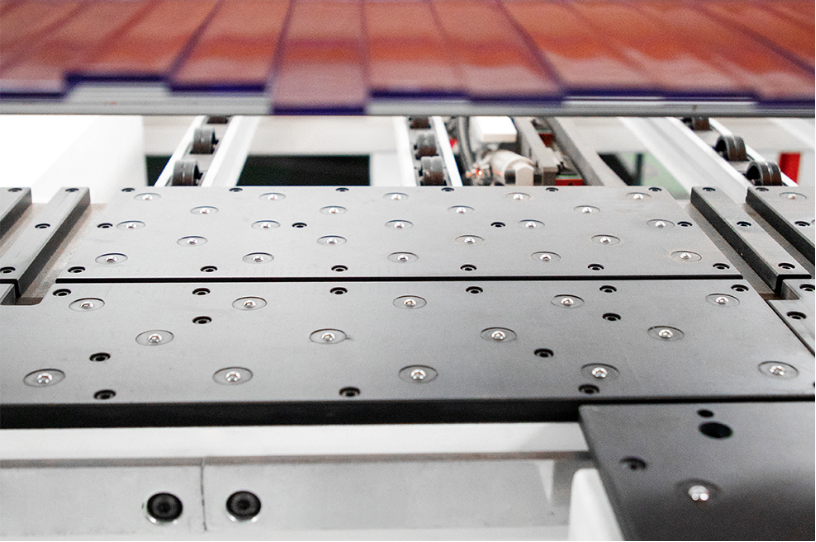

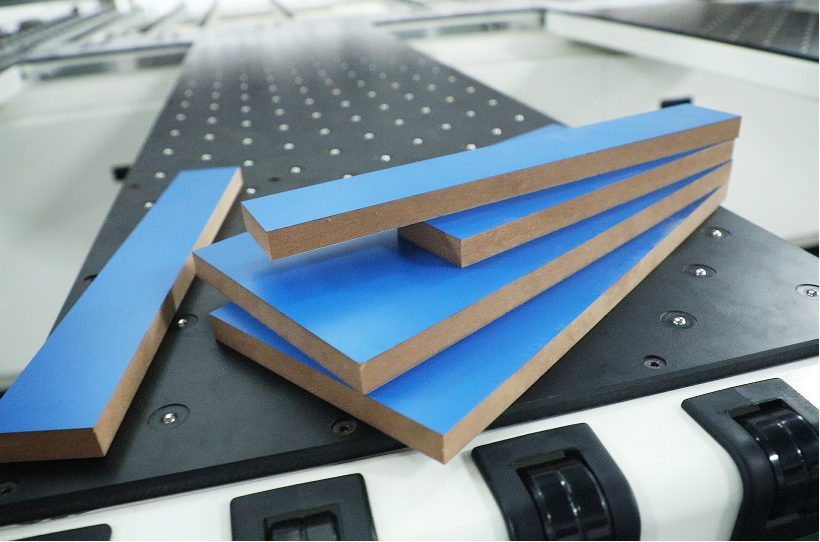

Countertop upgrade design

The table is narrower, effectively preventing edge bursting; the 25mm thickened table is durable and does not deform; the 1.8m*3 air-floating table, with roller-assisted cutting, does not damage the surface of the workpiece

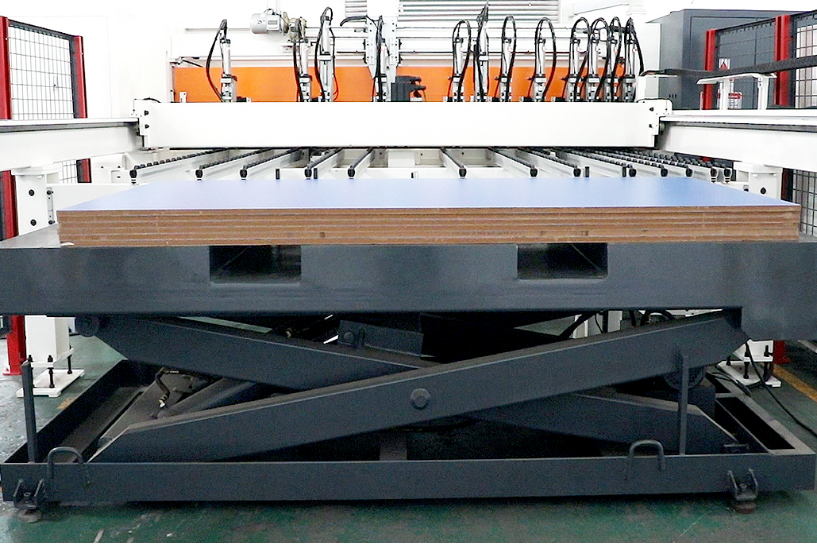

Lift table automatic loading

The lifting platform automatically loads materials, infrared rays locate the height of the upper plate, and automatically lifts to the corresponding height to improve efficiency and quality.

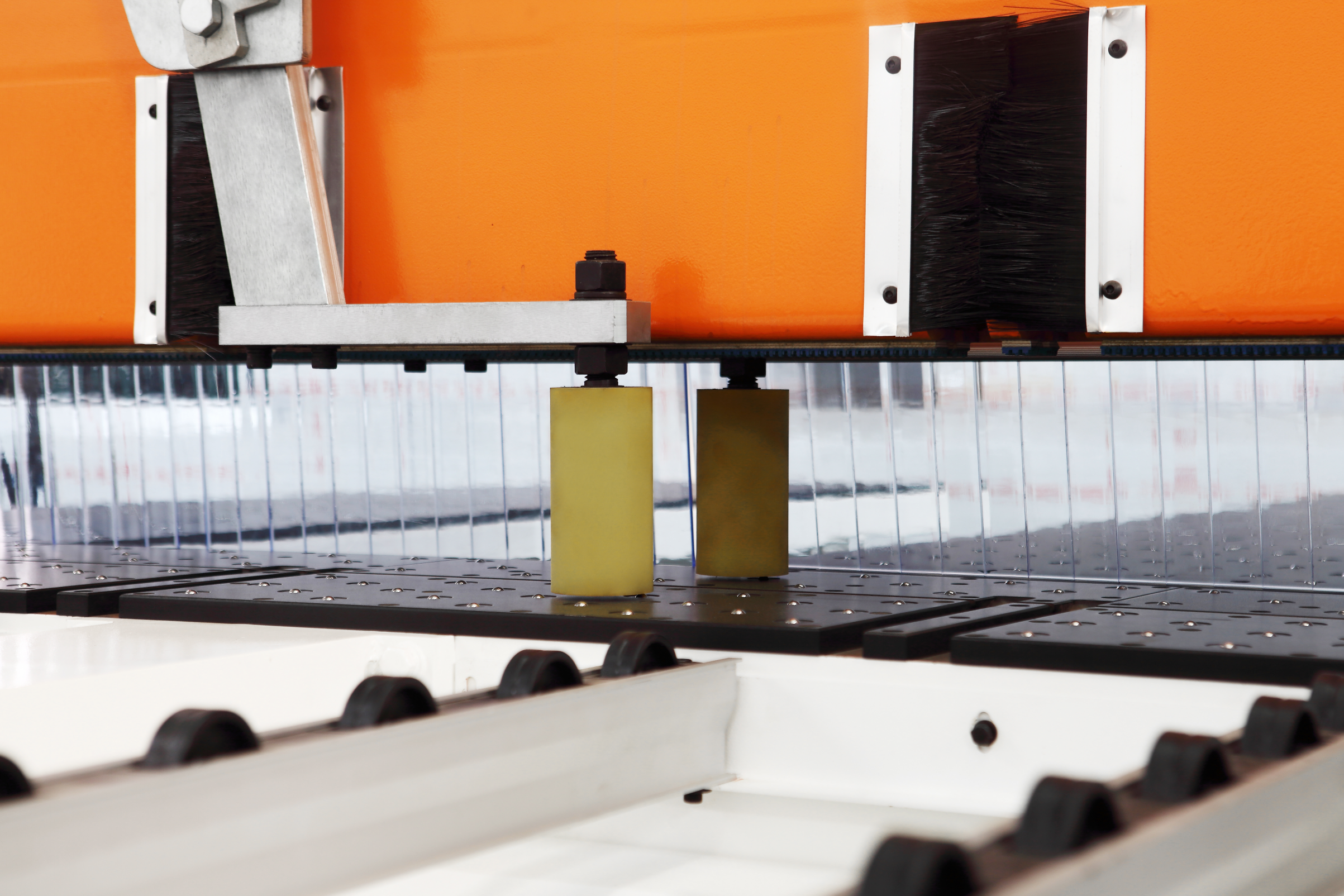

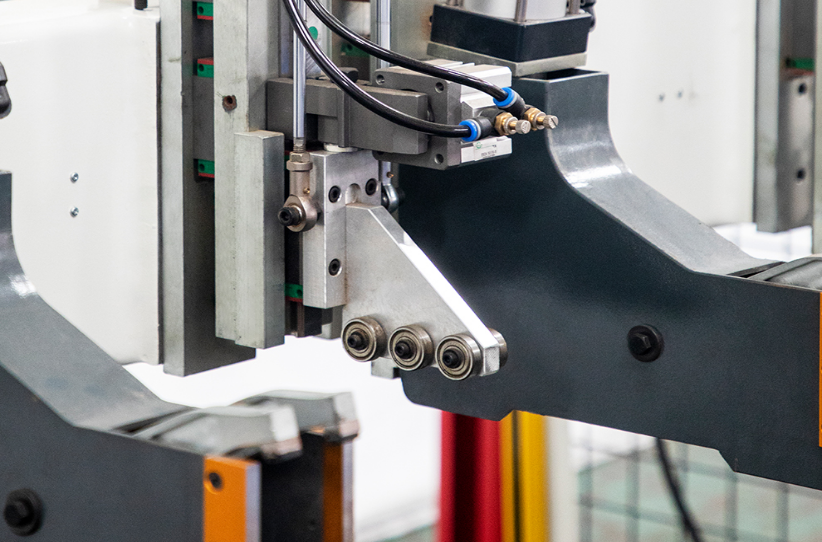

Rubberized two-finger structure

The two fingers are wrapped with glue to ensure stable feeding without damaging the workpiece. The speed can reach 85m/min. The glue-wrapped fingers prevent scratches on the surface of the board.

Magnetic scale positioning

2 positioning scrapers, magnetic scale to set the plate thickness according to the program, quick clamping

System optimization typesetting

22-inch large screen, the system can be connected with the order disassembly software, and has strong compatibility; PLC programming, comes with optimized layout, saving materials and reducing waste

High-speed cutting and wide application

Can be cut into particle board/multi-layer board/calcium silicate board/aluminum/acrylic and other materials, suitable for panel furniture/wood processing/building materials/customized furniture/American cabinets and other industries

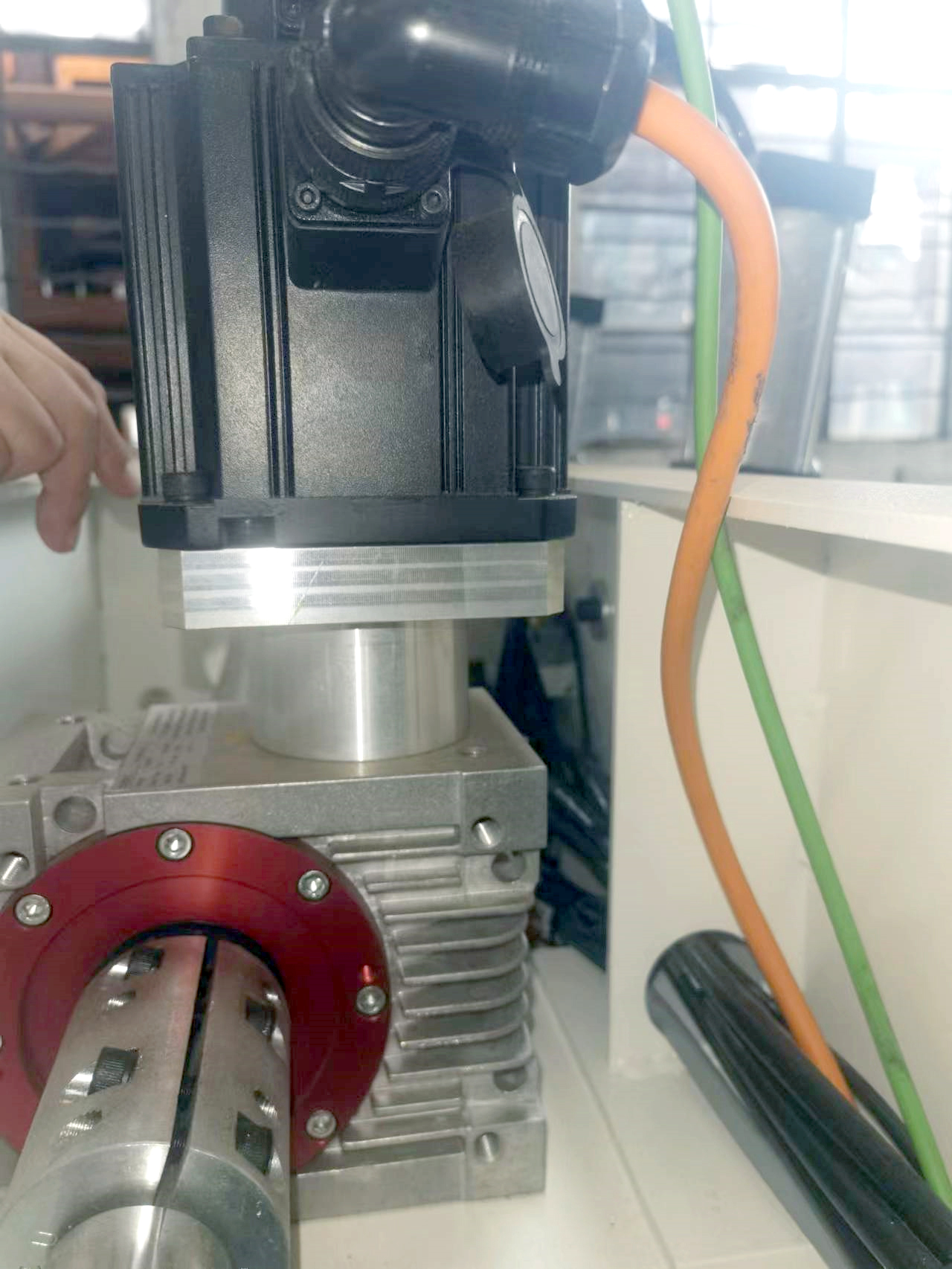

High precision gear rack

It adopts 6-level grinding and rack-and-pinion transmission, which is precise and stable, has excellent wear resistance, and can maintain long-term stable transportation.

Emergency pull switch

When an abnormality occurs during the operation of the equipment, just pull the nearest shutdown cable to cut off the power and shut down the equipment.

Reducer

The reverse gap is smaller and the processing accuracy is within ±0.1mm, ensuring the stability of the plate when it is transferred to each processing unit.

Automatic oil filling system

Automatic timing and quantitative oil injection lubrication ensures long-term operational stability and smooth processing, and extends the service life of the machine.