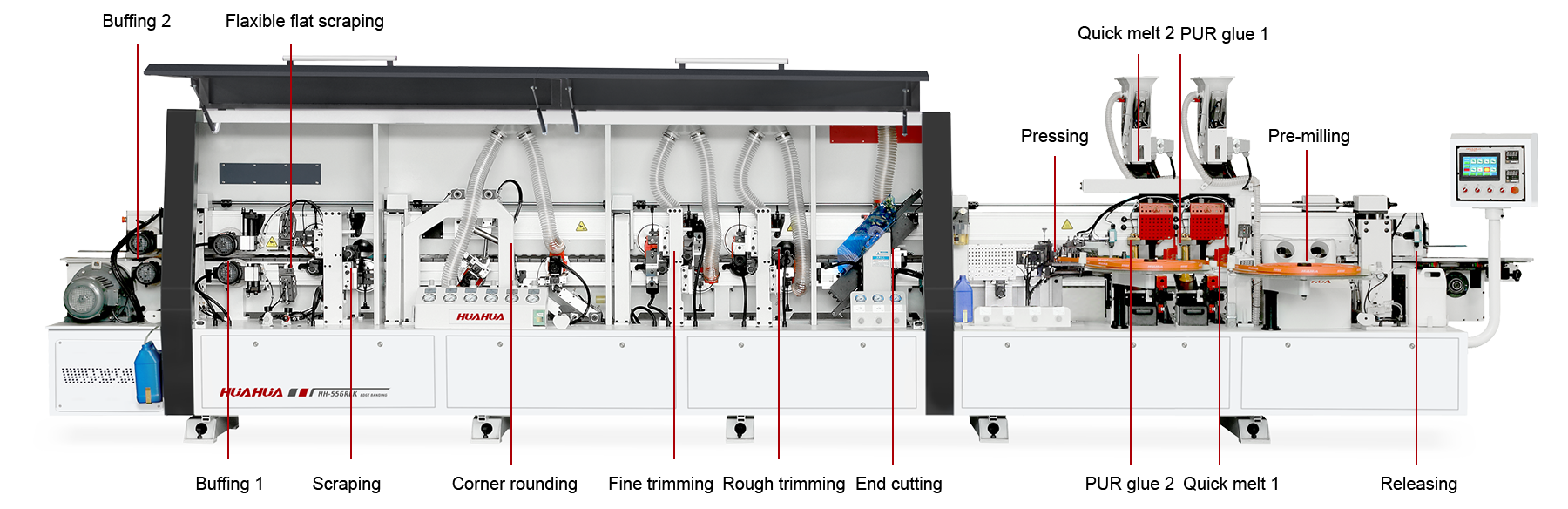

Features

Double PUR Glue Pot

The advantage of the double glue pot is that according to different colors of panels and different colors of edge banding, you can choose different colors of glue to solve the problem of glue lines

Quick Sol Device with automatic glue suction device

It only takes 15 minutes to start working at the fastest, and there is no need to wait for the glue to melt during mass production. Avoid the trouble of manual gluing, work uninterruptedly, and avoid dry burning of the glue pot. automatic glue suction device , no need work add the glue all the time with big Glue storage tank

Pressing wheel: 4 pcs strong pressing wheels and 1 pcs rubber wheel

4 pcs powerful pressure wheels with 1 pcs rubber wheel, the diameter of the increased pressure wheel is 150mm

The built-in scraper sprays the remaining glue, and the rubber wheel has better coverage and a tighter fit.

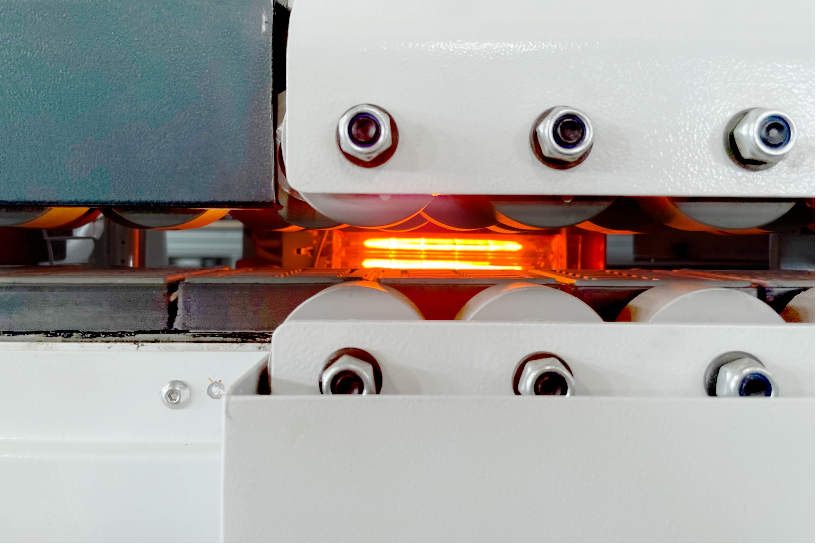

Bake Light

Bake Light -preheating, avoid degumming

After the baking lamp preheats the edge of the board, the glue is applied to seal the edge more tightly, and the edge band is pasted more firmly, which can avoid the problem of degumming caused by large temperature differences

Independent lifting of the pressure beam

The pressing unit, aligning unit and tracking unit all use independent lifting to prevent the panel from shaking and shifting, making it tighter and more stable, with precise edge banding.

Optional - Small board feeding aid

Auxiliary small boards enter the edge banding machine for processing to ensure the straightness of the small boards, prevent springboards, and ensure the edge banding effect.

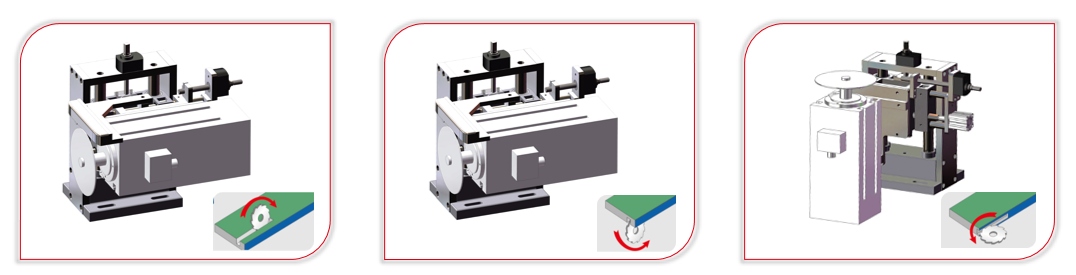

Optional - Custom Grooving Devices

We can customize according to customer needs: upper slot T, lower slot H, side slot S